Introduction of Turbomachinery Vibration Data Analysis

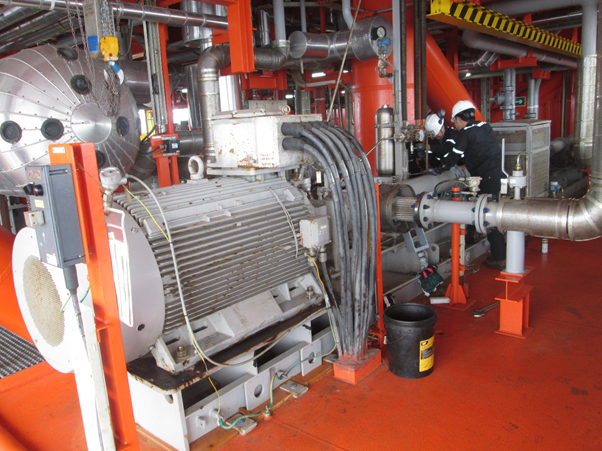

Turbomachinery Vibration Data Analysis is standard practice in monitoring condition of the equipment without interrupting operation of the machine.

Early Identification of problem allow operation team to schedule maintenance and avoid catastrophic failure of equipment and minimize loss of production opportunity.

How the technology works

Application of 32-channels vibration analyzer and data collector allow technician to collect sufficient information of the equipment to identify problem area with appropriate planning for such situation.

Application and problem detection of Turbomachinery Analysis

- Rotor instability due to aerodynamic.

- Misalignment and imbalance.

- Internal rubbing.

- Oil whip and oil whirl.

- Mechanical looseness.

- Soft foot.

- Gear problems; e.g. wear, broken gear tooth, bearing worn-out, unusual gear mesh frequency, etc.