What is Time-of-flight diffraction (TOFD) method

Time-of-flight diffraction is one of the most reliable non-destructive testing methods that can precisely identify the defect size and defect’s details. Normally, measuring the amplitude of reflected signal is a relatively unreliable method of sizing defects because the amplitude strongly depends on the orientation of the crack. Instead of amplitude, TOFD uses the time of flight of an ultrasonic pulse to determine the position and size of a reflector.

How does it work?

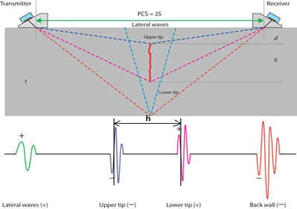

a pair of ultrasonic probes sets on opposite sides of a weld. The transmitter probes sent an ultrasonic pulse and is picked up by the receiver probe on the other side. In normal condition pipes, the signals picked up by the receiver probe are from two waves: one that travels along the surface and one that reflects off the far wall. When a crack is present, there is a diffraction of the ultrasonic wave from the tip(s) of the crack. Using the measured time of flight of the pulse, the depth of a crack tips can be calculated automatically by simple trigonometry.

Application of Time-of-flight Diffraction (TOFD)

TOFD usually being use along with Phased Array method to inspect pipeline weld or vessel both in pre-service and in-service inspection.

Problem detection

- Welding joint of pipeline or vessel

- Corrosion

- Depth of the defect or crack