What is Eddy Current Inspection

Eddy current inspection is used to detect defects or cracks at or near the surface without requirement to remove paint on the test subject. It has an advantage over other methods as the probe is small and able to reach difficult-to-access area such as socket weld and weld joint corners.

How does it work?

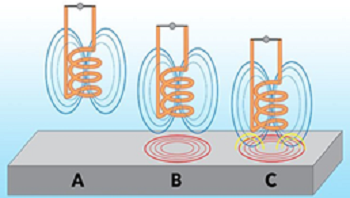

Eddy current testing is based on the physics theory of electromagnetic induction. An eddy current probe is generating an alternating current flow through a wire coil producing an oscillating magnetic field. The magnetic field is moving through metal test object. Changes in metal thickness or defects will interrupt or alter the amplitude and pattern of the eddy current. The eddy current instrument plots changes in the impedance amplitude and phase angle, which can be used by an inspector to identify defects in the test piece.

Application of Eddy Current Inspection

- Detect defects of metal test piece

- Defines thickness

- Corrosion detection

- Conductivity testing

- Welding inspection

Problem detection